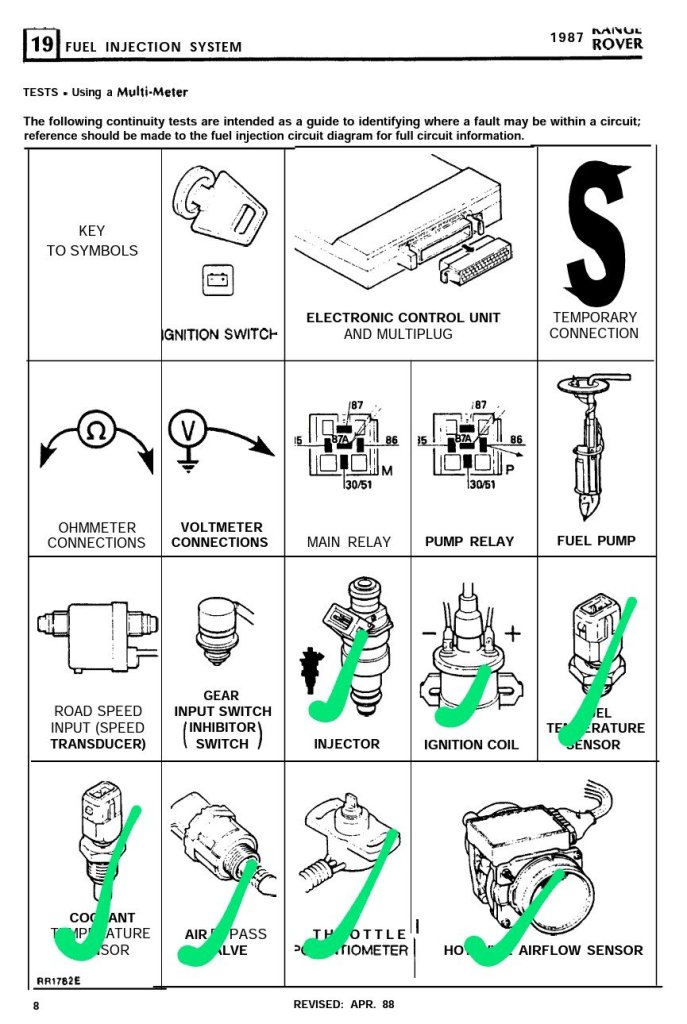

Perhaps the most trickiest job I’ve done on the car so far but I wanted to check the sensors connected to the ecu were performing within their correct ranges rather than systematically replacing these items in search of a slight misfire. I have the Continuity Checking Procedure Document which explains how to take various voltage and resistance readings at the ecu connector.

I disconnected the main plug from the ecu then carefully stripped back the tape to open up the outer protection ducting to expose the cables and then slid the plug cover up the loom a few inches. Then released the ecu from its mountings and reconnected the plug with all the pinout wiring all exposed.

So hopefully this saves me having to systematically replacing all the sensors in tracking down the misfire I have.

I then followed the continuity checks on all the engine sensors and compared the readings to the acceptable ranges. All were OK. I didn’t do the tests relating to fuel at this stage as it became more complicated.

I’ve previously tested or replaced all ignition components and now I am pretty certain the fuel control system is OK …….. so I suspect that it must be a mechanical problem that air is leaking into the manifold/air intake system from somewhere. The misfire is not bad it is just noticeable when the engine is ticking over and at low revs up to 1800rpm under no load. There’s no misfire (that I can tell) whilst the engine is under load …. that is during accelerating or constant speed.

So next I’m going to start checking the connections into the plenum chamber.